Have you ever felt that finding a decent CNC machine shop in the Philippines is like playing the lottery?

You send out a drawing with a clear ±0.01mm tolerance. But what you get back? It looks like a high school shop project.

This really gives engineers in Manila and Laguna a headache.

When your production line is waiting for that one specific jig to run, a supplier’s "small mistake" becomes your personal crisis.

Sure, a quick search for CNC Services turns up hundreds of results. But how do you tell a professional Machining Manufacturer apart from a middleman who just outsources everything?

It’s actually easier than you think.

This isn’t a textbook lecture. It’s a field-tested checklist to help you filter out the "garage shops" and find a partner who actually respects your specs.

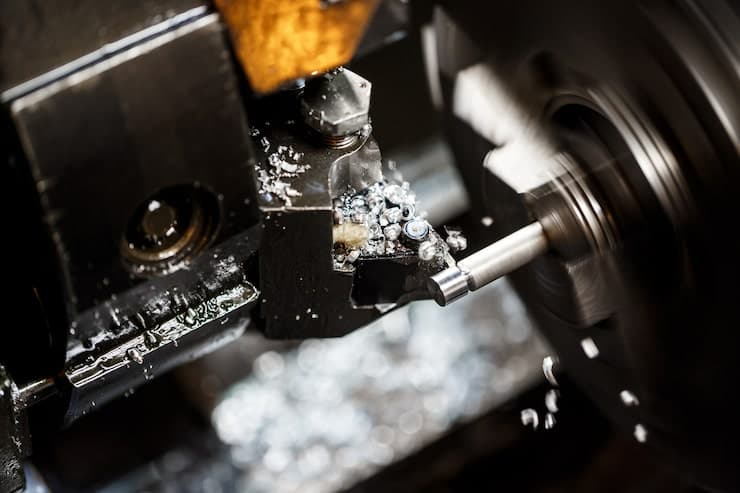

Equipment List: Do They Have the Firepower?

This isn't about counting how many machines they have on the shop floor.

It’s about asking: Do they have the right gun for your specific target?

Why "We do everything" is a red flag?

If a supplier tells you they handle everything from simple wood routing to aerospace titanium parts, run away.

In the world of Precision CNC, being a "Jack of all trades" usually means they are a master of none.

A professional Machining Manufacturer will look you in the eye and say: "We specialize in 3-Axis Milling," or "Our strength is complex Turn-Mill components."

Think about it. You wouldn't ask an eye doctor to remove your appendix, right?

So why trust a generalist shop with your tight-tolerance parts?

The "Firepower" Checklist:

Before you send that RFQ, ask them these specific questions:

Specialization: Do you focus on Milling or Turning?

Capacity: What is the maximum size (travel distance) your machines can handle?

Materials: Do you have dedicated machines for steel to avoid contaminating aluminum parts?

Honesty about their limitations is often the best sign of a reliable partner.

Further Reading: Still confused about machine types? Check out this guide on 3-Axis vs 5-Axis CNC Machining to understand what your part actually needs.

2. Inspection Reports: No Data, No Deal

In the world of Precision CNC, "trust" is good, but data is better.

If a shop hands you a batch of parts without an inspection report, they aren't manufacturing. They are gambling with your budget.

Are your parts "Measured" or just "Guessed"?

Machining is a dynamic process. Tools wear down, temperatures fluctuate, and machines drift.

Running a high-speed CNC job without a CMM (Coordinate Measuring Machine) to verify dimensions is like driving a sports car with your eyes closed.

You might hit the target once, but you will eventually crash.

Here is the dirty secret of many low-cost CNC Services in the Philippines:

They often skip this step to save time. They use a simple caliper to check the first part, and then assume the next 99 are perfect.

The result?

You find out the hard way—right on your assembly line—that the mounting holes are 0.05mm off-center. By then, it’s too late.

The "QC" Checklist:

Don't let suppliers guess. Ask for these proofs before you sign the PO:

CMM Capability: Do you have a CMM for complex geometries that calipers can't reach?

OQC Report: Will you provide a Final Inspection Report with every shipment?

Calibration: How often do you calibrate your measuring instruments?

If they hesitate to let you visit their QC room, it’s usually because they don’t have one.

Further Reading: Why is quality control non-negotiable? Read about The Importance of CMM in Modern Manufacturing to see how it guarantees your tolerances.

3. Material Traceability: Don't Let "Recycled Junk" Ruin Your Reputation

Have you ever received a CNC machining price that seemed too good to be true?

Be careful. In this industry, the devil is often hidden in the raw material.

The Secret Behind the Suspiciously Low Quote

Here is a common scenario in the local market:

You ask for AL6061-T6 because you need structural strength. But the shop uses cheaper, recycled aluminum or mixes in AL6063 (which is softer and gummier) without telling you.

On the surface, they look exactly the same.

But once you send the parts for anodizing, the nightmare begins. The color comes out uneven and blotchy.

Or worse, the threads strip out during assembly because the material was too soft.

A reputable Machining Manufacturer never plays games with material. They know that saving a few pesos on metal can cost you millions in reputation.

The "Material" Checklist:

Protect your product integrity by asking these three questions:

Mill Certificates: Do you provide material certs with every batch?

Segregated Storage: Do you have a dedicated rack for different alloys to prevent mix-ups?

Scrap Management: How do you handle scrap? (A messy scrap pile often hints at messy material control).

If they can't trace where the metal came from, you shouldn't be buying it.

Further Reading: What is a Mill Test Report (MTR)? Read Understanding Material Certifications to learn how to read the paperwork that proves your metal is real.

4. Communication & Location: Why "Near Me" Actually Matters

In the age of globalization, you can order parts from anywhere. But in the world of manufacturing, distance is risk.

Why "Importing" is often a trap for urgent projects

It sounds great to save 10% by outsourcing to an overseas supplier.

But when your production line is halted because a critical fixture is stuck in Philippines Bureau of Customs, that 10% saving becomes a joke.

For companies based in Manila, Cavite, or Laguna, choosing a local CNC Machine Shop isn't just about patriotism—it’s about survival.

The "Local" Advantage:

Imagine a design change is needed immediately.

Option A (Overseas): You send an email, wait 24 hours for a reply, struggle with language barriers, and wait another week for the modified sample.

Option B (Local): You drive two hours to the shop, discuss the DFM (Design for Manufacturability) face-to-face with the engineer, and pick up the modified part the next day.

Speed is the new currency. A supplier who can react in 24 hours is worth more than a supplier who is 5% cheaper but 2,000 miles away.

The "Logistics" Checklist:

Proximity: Are you located within driving distance of major industrial zones (PEZA)?

Language: Can your engineers discuss technical specs in fluent English? (Crucial for avoiding misinterpretation).

Delivery: Do you have your own delivery fleet, or do you rely entirely on 3rd party couriers?

Internal Link: Need parts in a rush? Check out our case study: Semiconductor Fixture Rescue: Delivered in 48 Hours to see how local agility saved a client’s project.

5. Quote Transparency: No Hidden Fees

Getting a CNC machining price is easy. Getting a transparent one is hard.

If a supplier sends you a quote with just a single lump sum number—run away.

How to spot the "Black Box" trap?

A vague quote is a breeding ground for hidden costs.

You might think the price is locked in. But halfway through the project, they’ll hit you with "unforeseen tooling costs" or "overtime fees" because they didn't calculate it right the first time.

A professional Machining Manufacturer breaks it down. We treat your money like it’s our own.

We don't just give you a price; we give you a solution.

For example, if we see a sharp internal corner that requires an expensive EDM process, we will tell you:

"Hey, if you change this radius from 0.5mm to 1.0mm, we can use a standard end mill and save you 30%."

That is the difference between a partner and a vendor.

The "Price" Checklist:

A trustworthy quote should be clear as glass. Look for these line items:

Material Cost: Separate from machining time.

Setup Fee: This should be a one-time cost (NRE), not charged per part on repeat orders.

Surface Finishing: Anodizing or plating should be listed separately.

DFM Feedback: Did they offer any suggestions to make your part cheaper to make?

Further Reading: Want to lower your costs legally? Read this guide on Design for Manufacturability (DFM) Tips to see how small design tweaks can save you big money.

Stop Gambling with Your Production Line

Finding a reliable CNC Machine Shop is a lot like finding a good mechanic or a trustworthy barber.

Once you find the right one, you stick with them for life.

You have enough things to worry about—design constraints, assembly deadlines, and budget limits.

Worrying about whether your supplier will actually deliver on time shouldn't be on that list.

If you are tired of the "hit-or-miss" quality in the local market, or if you have a project that simply cannot fail, let us take a look.

We don't just machine parts; we engineer peace of mind.

Ready to start?

Don't wait for another delay to happen.

[Upload Your Drawing (STEP/PDF)] for a FREE DFM Review today.

We are based right here in the Philippines. We speak your language, we understand your urgency, and we are ready to run.

Contact Yu Cheng PH now, and let's get your production moving.